Lenses are the heart of every pair of glasses, the part that actually improves vision. Yet for all their importance, they remain one of the most overlooked and least understood elements in eyewear production.

For decades, the way lenses have been manufactured has stayed largely the same, starting with semifinished blanks, manual adjustments, long timelines, and ending at lots of back-and-forth. But the industry is changing. Newer technologies, especially AI and 3D tools are improving how lenses are designed, produced, and visualized.

In this article, we’ll you walk through how modern lens manufacturing works, where traditional processes still dominate, and how AI-powered eyewear platforms help. You will also get to know hoe VARAi is helping manufacturers, optical retailers, and DTC brands digitize faster, reduce waste, and get to market with more confidence and edge.

What Are Eyewear Lenses Made Of?

When we talk about eyewear advancements, most of the focus lands on frame design. Yet the optical lens materials inside those frames carry the real responsibility of vision correction. Whether it’s a single-vision reader or a complex progressive lens, every lens begins with one critical choice of material between glass vs. plastic.

Mineral (Glass) Lenses

Once the industry standard, mineral glass offers unmatched optical clarity and scratch resistance. But it comes with its own trade-offs. These lenses are heavier, more fragile, and far less common today. According to the Vision Council, less than 5% of prescription lenses sold in the U.S. use real glass due to safety concerns and weight issues.

Organic (Plastic) Lenses

Plastic has largely taken over from standard CR-39 to high-performance options like polycarbonate and Trivex. These materials are lighter, safer, and more adaptable. High-index plastics, for instance, offer thin, sleek profiles for strong prescriptions, making them a favorite for modern eyewear designing.

Other Lens Types

From single vision to bifocals and progressives, lens types vary by purpose. Bifocals offer distinct zones for near and far vision, while progressive lenses provide smooth transitions. These complex surfaces require precision and customization.

Stock vs. Semi-Finished Lenses

Most lenses start as either stock lenses or semifinished blanks.

- Stock lenses are mass-produced using a casting process, affordable and fast, but with limited customization.

- Semi-finished lenses are customized on the back using free-form technology for ultra-precise, wearer-specific optics.

The shift to free-form lenses is transforming optics, with AI tools like VARAi streamlining material selection and curvature decisions early and accurately.

Step-by-Step Process of Traditional Lens Manufacturing

Before AI eyewear tools and digital workflows became integrated into the lens manufacturing process, many manufacturers followed a meticulous, manual series of steps. And while many labs have upgraded their equipment, the core method hasn’t changed much in decades.

Here is how small to medium or even big lens manufacturing companies work:

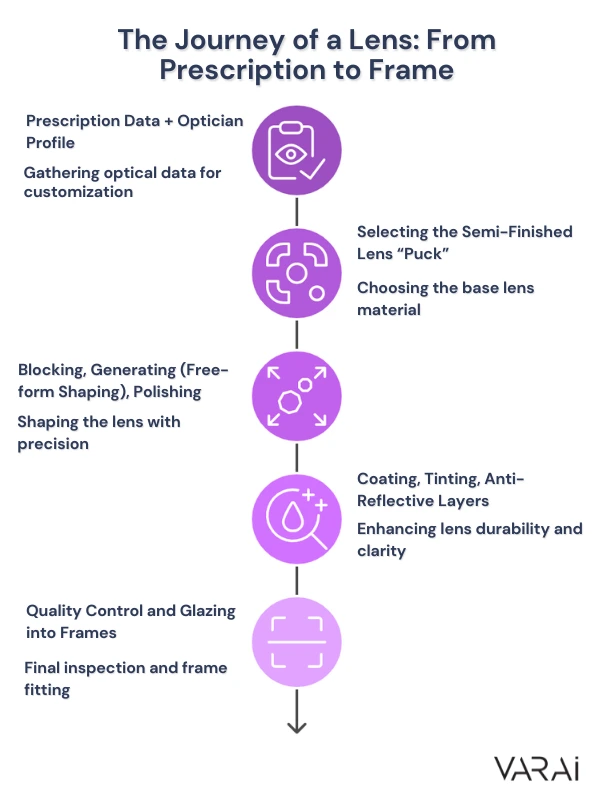

1. Prescription Data + Optician Profile

Every lens starts with a unique set of optical data, sphere, cylinder, axis, prism, and fitting measurements like pupillary distance (PD) and segment height. These details guide the full prescription lens production process, especially for progressive and multifocal lenses.

2. Selecting the Semi-Finished Lens “Puck”

The next step is choosing a semifinished lens blank (often called a “puck”). This base lens has a molded front curve and an unfinished back surface, allowing full customization. The specific material is selected based on prescription strength, desired thickness, durability, and optical performance.

3. Blocking, Generating (Free-form Shaping), Polishing

The lens is secured using a blocker to ensure stability. Then, free-form technology (a high-precision, CNC-guided process) is used to cut the back surface to exact prescription specs. This method maps tens of thousands of data points, resulting in sharper, more personalized vision correction.

4. Coating, Tinting, Anti-Reflective Layers

Polishing smooths out any surface micro-level defects. Lenses are then coated for function and durability with any of the following coatings:

- Scratch-resistant coatings for softer plastics

- Anti-reflective layers for clarity and glare reduction

- UV-blocking filters to guard against harmful rays

Optional tints may be added here for sun or indoor/outdoor use according to manufacturers or optical stores directions.

5. Quality Control and Glazing into Frames

After all these necessities, each lens undergoes optical testing and visual inspection for one final inspection. Once approved, it’s edged into the exact shape of the chosen frame using automated machines. For rimless or custom designs, additional drilling or slotting is performed.

Why This Lens Manufacturing Technology Is Still Slow and Costly?

Despite decades of progress made in eyewear industries, lens manufacturing remains slow, costly, and difficult to scale. Most lenses still follow a one-by-one production model, and that adds up. Few of the reasons observed for slow manufacturing and production of eyewear lenses are:

Long Lead Times

It can take anywhere from 6 to 9 months to go from prescription to product, especially when prototyping, coatings, and frame integration are involved. According to industry data, even mid-sized labs often operate with backlogs of 3–5 weeks per lens order.

High Minimum Order Quantities (MOQs)

Customized lenses require dedicated machine time and setup. For smaller brands or DTC retailers, this typically means over-ordering or, worse, getting priced out of premium materials and coatings.

Wasted Prototypes & Reworks

Many design choices aren’t truly visible until a physical prototyping sample is produced. That results in discarded pucks, re-grinding cycles, and shipping costs, all before final approval.

Manual Errors & Bottlenecks

Blocking, edging, and polishing steps still rely on human oversight. Even small misalignments can lead to optical distortions or surface damage, that can be costly to fix.

Logistics Overhead

Each sample shipped across regions for feedback or final approval adds to both cost and timeline. In a globalized eyewear supply chain, this can be one of the biggest reasons for lower profits and margins.

Due to all these reasons, it becomes clear that the traditional lens manufacturing process wasn’t built for speed, flexibility, or modern scalability. Especially when we consider the newer technologies launched to make each step of the process digitized.

The Future of Lens Design Is Digital And AI Is Leading the Way

The eyewear industry is entering a new era, and AI in eyewear design is what’s powering it.

Instead of relying solely on physical prototypes and guesswork, brands can now create digital twin lenses that serve as fully functional design assets from day one. This transformation is possible with VARAi, the AI-powered eyewear design platform. Let’s see what all you can do with our advanced AI tools for eyewear:

From CAD to 3D in Seconds

VARAi turns your lens designs or CAD files into hyperrealistic 3D renders, complete with real-time curvature mapping and material simulation. You can preview free-form surface modeling with precision and adjust designs instantly without waiting for a prototype.

Smarter Material Selection

AI-driven tools connect your designs to a live supplier database, matching lens materials based on thickness, availability, and cost. This makes sampling and supply chain decisions faster and smarter, especially for brands managing complex OEM workflows.

Digital Twins Across the Pipeline

One 3D digital lens model can now power multiple use cases:

- Design iterations and refinements

- Virtual Try-On (VTO) for customer experiences

- Automated content creation: from pack shots to campaign visuals

- Sampling without a single physical lens

Whether you’re an independent designer or scaling through OEMs, AI eyewear tools like VARAi are setting the new standard, where agility, precision, and creativity no longer come with trade-offs.

The New Lens-to-Launch Workflow with VARAi

Your lens isn’t just an optical element anymore, it’s your content engine.

With VARAi’s AI-powered ecosystem, brands can move from lens design to campaign launch without a single prototype or photo shoot. This is what the future of virtual lens prototyping looks like

One 3D Model, Infinite Outputs

Once your lens is rendered in 3D, it becomes a digital twin that powers:

- Virtual Try-On (VTO) experiences

- Marketing visuals and pack shots

- AI model photoshoots — without models, light boxes, or location costs

- Hero visuals for e-commerce, billboards, and retail catalogs

Up to 70% Savings in Marketing Asset Creation

Eliminate the cost of photographers, studio rentals, rights management, and post-production. Render everything, even in 8K, directly in-browser.

AI-Powered PD Measurement Tool

For DTC brands, VARAi includes a seamless, device-agnostic PD measurement AI tool that delivers optometrist-grade results in under 10 seconds, no clunky props or apps required.

True Eyewear Marketing Automation

From digital design to AI-generated content, VARAi replaces fragmented workflows with a scalable, studio-free solution. Whether you’re an OEM or boutique brand, you can launch faster, smarter, and leaner, without compromising on quality.

Who Benefits from This New Lens Workflow?

VARAi’s AI-powered eyewear design tools are not just for hacking consumer data. They can also help you scale design and production equally. You can benefit from this new lens manufacturing process if you are:

OEM Manufacturers

Accelerate prototyping, reduce human error, and cut production waste. With CNC-ready models and digital twin lenses, VARAi enables faster and leaner factory operations.

DTC Eyewear Startups

Launch collections without touching a prototype. From PD measurement AI tools to 3D eyewear rendering software, everything you need is browser-based and built to scale.

Optical Chains & Private Labels

Customize SKUs, preview materials, and create fully branded campaigns in days, not quarters. All marketing assets can be generated up to 120 days pre-launch.

Independent Designers & Opticians

Design freely with fewer MOQs and full creative control. Real-time virtual lens prototyping levels the playing field.

Whether you’re producing 10,000 units or designing one hero frame, VARAi helps you move faster, smarter, and without compromise.

Final Thoughts

Lenses may have been overlooked in the eyewear value chain, but not anymore. As design, production, and marketing go digital, AI tools like VARAi are helping brands reclaim control.

Whether you’re scaling collections or crafting custom pieces, modern lens manufacturing is no longer about catching up, it’s about leading with speed, clarity, and vision.

FAQs

Q1. How long does lens production usually take?

Traditional lens production takes 6–9 months. With AI tools like VARAi, you can cut timelines down to days, from concept to campaign launch, all in-browser.

Q2. What is free-form lens technology?

It’s a CNC-guided process that sculpts lenses with extreme accuracy. Thousands of data points are mapped for sharper, personalized optics, especially in complex prescriptions.

Q3. How does VARAi improve lens production?

VARAi digitizes the full workflow. From real-time 3D modeling to AI-generated visuals, it speeds up design, cuts waste, and helps launch collections without delays.