Designing eyewear used to take at least 9 months of trial and error. This back and forth had created a loop of no product or manufacturing success. However, today, rapid prototyping eliminates development time by half or sometimes down to even a month.

But how does this happen?

In this article, we will help you understand what rapid prototyping is, its types, and methods. If you are a manufacturer, e-commerce business owner, lens manufacturer, or just someone who falls within the eyewear value chain, keep reading to know what you gain from fast eyewear prototyping.

Key Takeaways:

- Rapid eyewear prototyping reduces product development from 9 months to as little as 1 month.

- It improves design speed, flexibility, cost efficiency, and early flaw detection.

- Common methods include 3D printing, CNC machining, handmade prototypes, CAD-based designs, and aesthetic finishing.

- Tools like SLA 3D printers and diamond turning machines support high-fidelity optical prototypes.

- VARAi’s 3D Configurator enables full eyewear collections to launch within 45 days at under $100 per design.

- Rapid optical prototyping helps manufacturers, designers, and e-commerce brands to innovate faster and lower risks.

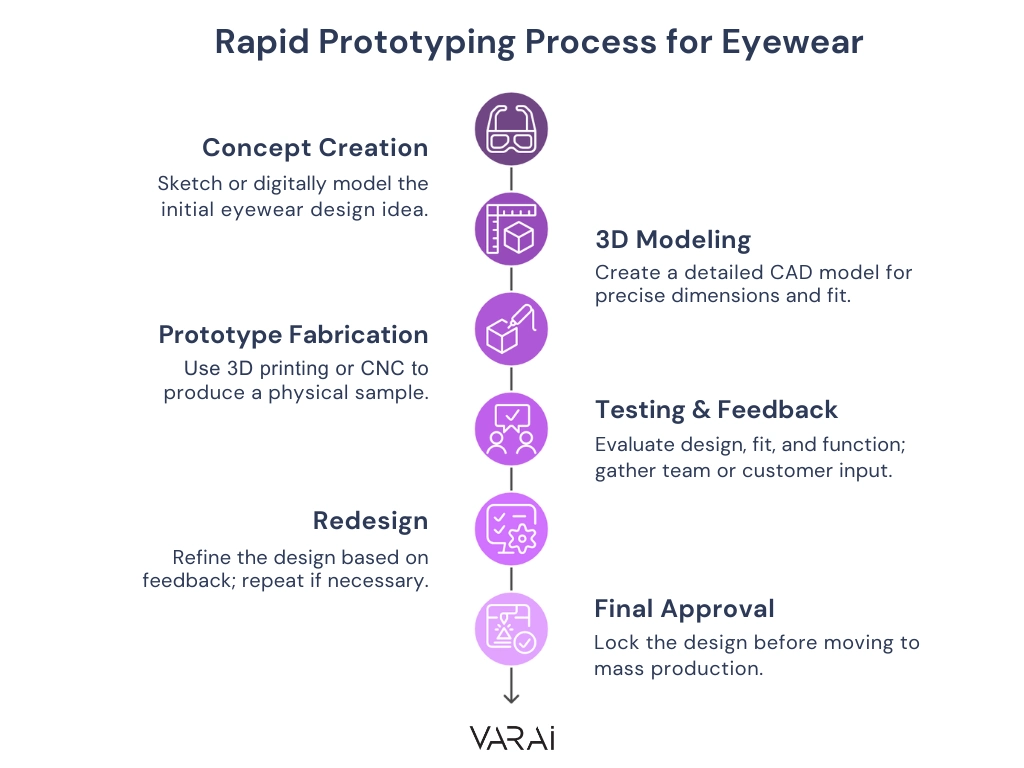

What is Rapid Eyewear Prototyping?

To define eyewear prototyping, we will have to first define what prototyping means.

Prototyping is the process of building a draft or rough version of a product or system to test and refine before final production. In eyewear, rapid prototyping allows for the creation of eyewear designs, and it’s various versions, in respect to color, shape, material type, and more.

It helps with the deployment of prototypes that are initial copies and then the changes and ultimate finalization of the product itself. Opticians, optical stores, manufacturers, eyewear designers, and others can use this technique to enhance their design-for-manufacturing optimizations.

Through rapid prototyping of eyewear, you can:

- Speed and Efficiency: Quickly test and refine eyewear designs to accelerate time-to-market.

- Design Flexibility: Experiment with multiple design variations before committing to production.

- Cost Effectiveness: Use simplified materials and methods to cut costs and lead times.

- In-House Manufacturing: Integrated facilities speed up production and streamline the entire workflow.

- Risk Reduction: Early prototypes reveal design flaws before full-scale manufacturing.

Top Methods of Prototyping Eyewear

There are many different methods of eyewear prototyping. An eyewear seller or supplier can think of manufacturing their eyewear designs in multiple different ways before the production process even begins. We have listed the most popular and useful ones down below.

3D Printing

At the moment, the global 3D printed eyewear market is currently valued at $1.2 billion. 3D printing for eyewear works by generating physical sample copies of the digital files. It is also known as additive manufacturing and makes the process of eyewear creation efficient and customizable. 3D printing is a great way to play with intricate designs like lattice structures that are nearly impossible to replicate with traditional methods.

You can use technologies like:

- PolyJet

- Nylon-Based Printing

And if you are wondering which stage of manufacturing this method is best for, it is made for early-stage prototypes with functional testing.

CNC Machining

Computer-numerical control machines (CNC) are an option for eyewear design and prototype. They are usually attached to various cutting tools to make sure that the prototypes are carved and shaped properly. CNCs can be used with different materials, like acetate sheets, metals, or composites.

The best part? This technology is known for bringing precisions of up to micron-level accuracy of ±0.005 mm (5 microns) and ±0.0005 mm (0.5 microns). High-end machines can deliver up to ±0.002 mm (2 microns).

There are at least 5 types of CNC machines:

- 3-Axis CNC

- 4-Axis CNC

- 5-Axis CNC

- CNC Lathe

- Swiss Lathe

Our research also shows that while CNC may be used by many businesses, it is very resource intensive though, making it one of the least popular options. Also, the average cost of locating such a machine and getting your designs done through CNC machining can cost around $35 to $200 per hour.

Handmade Prototypes

A thing of the past, handmade prototypes for eyewear were quite popular in the 1700s. Now, most prefer machine-made prototypes and the quick deployment behind it. Even though you can’t do mass production or multiple handmade prototypes, you can get custom, beautiful frame designs. Usually, eyewear brands who want to market themselves as artisanal choose to only get handmade prototypes.

The process is a bit traditional but worthwhile:

- Firstly, artisans select materials like acetate or metal, heating acetate for shaping.

- Secondly, frame parts are cut and shaped using hand tools or CAD-guided routers.

- Next, hinges, nose pads, and tips are assembled and adjusted manually for fit.

- Then frames are hand polished to smooth surfaces and improve the final look.

- Lastly, prototypes are tested and refined based on comfort and functionality feedback.

CAD-Based Digital Prototyping

CAD-based software like AutoCAD are used by eyewear designers to offer digital prototypes of potential future launches. This is the most cost-effective, quickest way to start your eyewear collection without spending any money on physical prototypes first. File formats, such as .DWG, .DXF are best to supply to for physically prototyping as these can easily get converted into 3D models using VARAi.

Rapid prototyping offers precise customization and detailed craftsmanship, capturing subtle luxury design elements. It helps detect manufacturing issues early, preventing costly errors, and serves as a vital physical reference for digital processes like CAD modeling and CNC machining.

Aesthetic Finishing Techniques

These techniques are usually applied to final prototypes to visualize a complete eyewear frame with correct lens fittings. It can help all stakeholders understand the visual appeal, tactile quality, and user experience. It tries to transform the raw or machined eyewear model into polished, stylish, and comfortable prototypes that can be envisioned as the final product for sale.

The 3 most popular aesthetic finishes used are:

- Laser Engraving: Uses a focused laser to permanently etch detailed logos or patterns on plastic, metal, or glass frames with high precision and durable results.

- Pad Printing: Transfers multicolor designs onto curved eyewear surfaces using silicone pads, allowing accurate, cost-effective, and repeatable printing on acetate and metal frames.

- Hot Stamping: Applies metallic or colored foil logos using heat and pressure, producing sharp, vibrant, and durable finishes ideal for luxury branding on frames.

Best Tools for Creating Fast Eyewear Prototypes

Not every tool you will come across will provide you the ability to have rapid eyewear prototyping abilities. But don’t worry, we have listed the top 3 tools on the market that can help you with optical prototype iteration, concept modeling, and manufacturing-ready design.

1. VARAi’s 3D Configurator

We provide the world’s first eyewear 3D configurator that allows all stakeholders to create, edit, shape, and finalize their eyewear design. It is especially useful for designers, manufacturers, and brand owners to collaborate on a single platform to launch their eyewear collections from start to finish within 45 days!

Top features:

- Centralized user interface

- Multi-functional features

- Less than $100 for creation

- Live changes updates

- Compatible for high-fidelity prototypes

- Allows creation of 3D printed jigs and fixtures

Also Read: How to Streamline Your Business with Eyewear Saas Solutions from VARAi?

2. SLA (Stereolithography) 3D Printers

SLA printers use a laser to cure liquid resin layer by layer, producing highly detailed and smooth prototypes ideal for eyewear frames. This technology supports fast iteration with excellent surface finish, making it popular for concept and looks-like prototypes.

Can cost up to $50 to $500 per eyewear model design.

3. Diamond Turning Machines

Used primarily for lens prototyping, diamond turning machines precisely shape optical surfaces on lenses and components with sub-micron accuracy. This tool is essential for creating high-fidelity optical prototypes quickly, especially for customized or free form lenses.

Only useful for lenses or glass-based components, and not materials like acetates.

At The End..

Rapid prototyping has transformed how eyewear is designed, tested, and brought to market. From 3D printing and CNC machining to artisanal handmade models, today’s methods support faster development, fewer errors, and greater creative control.

Whether you’re a manufacturer, e-commerce brand, or eyewear designer, embracing these tools means you can innovate faster, refine better, and launch smarter. With solutions like VARAi’s 3D Configurator, turning concepts into customer-ready eyewear has never been more accessible or more efficient.

If you want to try the tool for yourself, contact for a cost-free demo!