Imagine being able to see your eyewear design come to life, even before a single prototype is made. While many industries are still catching up, the eyewear sector has fully embraced digital visualization, and it’s changing everything.

Today, virtual eyewear visualization software and tools are embedded in nearly every stage of the eyewear manufacturing process. These technologies go far beyond aesthetic previews. They are enabling brands, designers, manufacturers, and stakeholders to view precise evaluations of materials, structural feasibility, and product performance. The result is faster prototyping, fewer errors, and a more efficient path from concept to consumer.

In this article, we’ll explore how digital visualization is powering customization, virtual try-ons, smart glasses, advanced lens design, and 3D printing. You’ll also discover how integrating these tools into your workflow can reduce production costs by up to 50%, without compromising on speed or quality!

1. Customization and Personalization

The demand for personalized eyewear has evolved. As a marketing tactic, most brands are ready to provide customization features, like changing colors or adding a custom design element.

Consumers today want frames that fit perfectly but also express their individual style. This is a different approach to standard shelf options and explores customer satisfaction on a deeper level. This is all possible because of digital visualization, using a powerful tool that enables customizations and scalability hand in hand.

With advanced visualization tools, such as 3D configurator, augmented reality viewer, virtual try-on tool, CAD modeling software, 3D rendering engine, and material simulation tool, both customers and designers can collaboratively explore numerous options, including:

- Frame shapes and bridge widths

- Color palettes and finishes

- Lens tinting variations

These tools generate photorealistic 3D models that update instantly, providing immediate feedback on how each choice influences the final product. This interactivity helps customers with real-time passive browsing into an engaging co-creation experience.

Consider a customer using a digital configurator on an eyewear e-commerce site. They can:

- Adjust frame size

- Choose between matte or glossy finishes

- Preview the frame on a virtual model of their own face

All before making a purchase. This process ensures the final product feels uniquely theirs.

Also read: 3D Configurator for Eyewear: What It Is and How To Use It?

2. Virtual Try-Ons

Virtual Try On Tools help support the “Try before you buy” notion and help consumers finalize products just from their screen.

Virtual try-ons are AR-powered tools that let users digitally preview how eyewear looks and fits on their face. It uses real-time facial mapping and 3D visualization technology. They have become a common functionality of modern eyewear e-commerce.

As online shopping habits are of various types, VTO tool helps grab the attention of customers, keeps them proactive in the website, and encourages buying behavior coupled with other strategies. Also, every 7 in 10 customers have cart abandonment, which is low sales. VTO can also help with that.

What makes them so effective?

- Sub-millimeter 3D facial recognition captures facial depth, contours, and proportions

- Augmented reality overlays simulate frame fit and style with real-time responsiveness

- Dynamic rendering adjusts with head movement, lighting, and viewing angles

If your value proposition is different, like with VTO, you can get up to a 31% increase in conversion rates. Many eyewear brands set up virtual try on so customers can select, pay, and pick their best frame. It can help mirror the confidence of an in-store fitting, without the need for any additional tools or needs.

3. Technical Design and Production

Many designers and manufacturers, who collaborate on an eyewear design and production process, depend on precision. Even a mismatched hinge placement, lens curvature, or the slightest deviation can affect comfort, durability, or visual accuracy.

That’s why Computer-Aided Design (CAD) and digital visualization have become essential in both the design and production of modern eyewear. Customers can use CAD technology to visualize, convert, and deliver accurate 3D models for production or approvals.

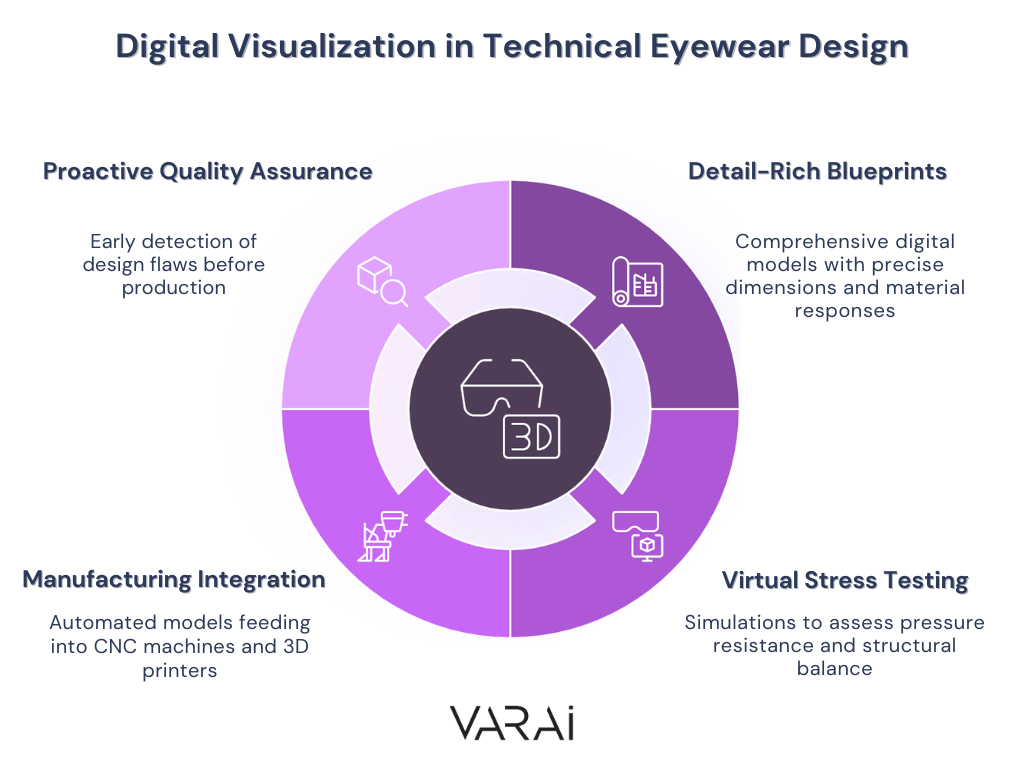

Here’s how digital visualization helps with technical eyewear design:

Detail-Rich Digital Blueprints

Designers create comprehensive digital models that include precise dimensions, material responses, tolerances, and stress points.

Virtual Stress Testing

Before any prototype is made, simulations assess pressure resistance, flex patterns, and structural balance. This sharply reduces the trial-and-error cycles.

Manufacturing Integration

These automated eyewear prototyping models feed directly into CNC machines, laser cutters, and 3D printers, ensuring production accuracy without the need for manual interpretation.

Proactive Quality Assurance

Visualization tools flag potential design flaws early. If there is an imbalance or overstrain at joints or some other design technicality that doesn’t sit right, corrections can happen before materials are even cut.

4. Smart Glasses in Manufacturing

Smart glasses represent one of the most complex categories in modern eyewear. Unlike traditional frames, they must integrate microelectronics, like sensors, batteries, cameras, and processors into lightweight, ergonomic designs.

The global smart glasses market is projected to reach USD 4,129.3 million (about $4.13 billion) by 2030, growing from $878.8 million in 2024 at a CAGR of 29.4%. This will prompt every eyewear brand to start strategizing in digital visualization to maintain a delicate balance between tech integration and wearability.

Through high-fidelity 3D modeling, designers and engineers can simulate the internal structure of smart glasses before anything is physically built. These models ensure that each component, from the curve of a wire to the thickness of a battery, fits within the frame without compromising comfort, aesthetics, or balance.

Key benefits of this approach include:

- Optimized spatial planning – Internal components are arranged efficiently to maintain slim, lightweight designs.

- Reduced physical prototyping – Virtual simulations replace multiple trial-and-error builds, saving both time and cost.

- Early issue detection – Designers can identify and address potential problems like heat accumulation or weight imbalance before production.

By enabling virtual prototyping of products, like eyewear, digital visualization shortens innovation cycles and simplifies troubleshooting, providing two of the most critical advantages.

5. Digital Lens Technology

Designing a high-performance lens today takes into consideration the correct prescription, performance, and precision. The process of creating a lens and then simulating its effects online is quite difficult. Though, digital visualization tools can help in understanding the various aspects of lens manufacturing before generating prototypes or samples.

Here’s how digital visualization is helping lens design and performance, especially for manufacturing companies:

- Light Behavior Simulation: Designers can simulate how light interacts with various lens geometries, predicting effects like refraction, lens thickness, and chromatic aberration, all in real-time.

- Coating & Filter Testing: Features like anti-reflective layers, UV filters, and photochromic transitions can be virtually applied and tested.

- Precision Personalization: Using real-time input, visualization software customizes lens parameters to suit facial structure, pupillary distance, and lifestyle habits to help with comfort and clarity.

- Digital Quality Assurance: Pre-manufacturing simulations detect flaws such as warping, edge inconsistencies, or optical distortion. This is helpful in avoiding expensive production errors.

By replacing trial-and-error with real-time performance previews, you can confidently finalize your lens production without much delay. The other results? Reduced waste and lenses made with scientific accuracy to each individual wearer.

6. 3D Printing for Eyewear

3D printing has revolutionized eyewear manufacturing. It offers unmatched speed, customization, and creativity. However, one of the best uses of 3D printing for eyewear is its environment friendly manufacturing. As per statistics, 3D printing reduces carbon footprint by up to 58% compared to traditional methods.

The effectiveness of 3D printing though is 100% dependent on digital visualization. Especially, using 3D models and 3D configurators for eyewear.

Before any printing begins, high-resolution 3D models have to be fed into the system in order for the machine to start printing. These can be created in software like Blender. Rather than using this software and a specialist in-house, you can also request 3D model digital replicas from VARAi.

Here’s how digital visualization supports and strengthens the 3D printing process:

➡ Spot weak points in eyewear design early, like thin areas or unsupported angles.

➡ Check the textures, colors, and shapes before printing.

➡ Make quick tweaks without needing multiple test prints.

➡ Adjust the fit and style for each user in seconds.

➡ Only print what’s needed, the approved models with no excess material.

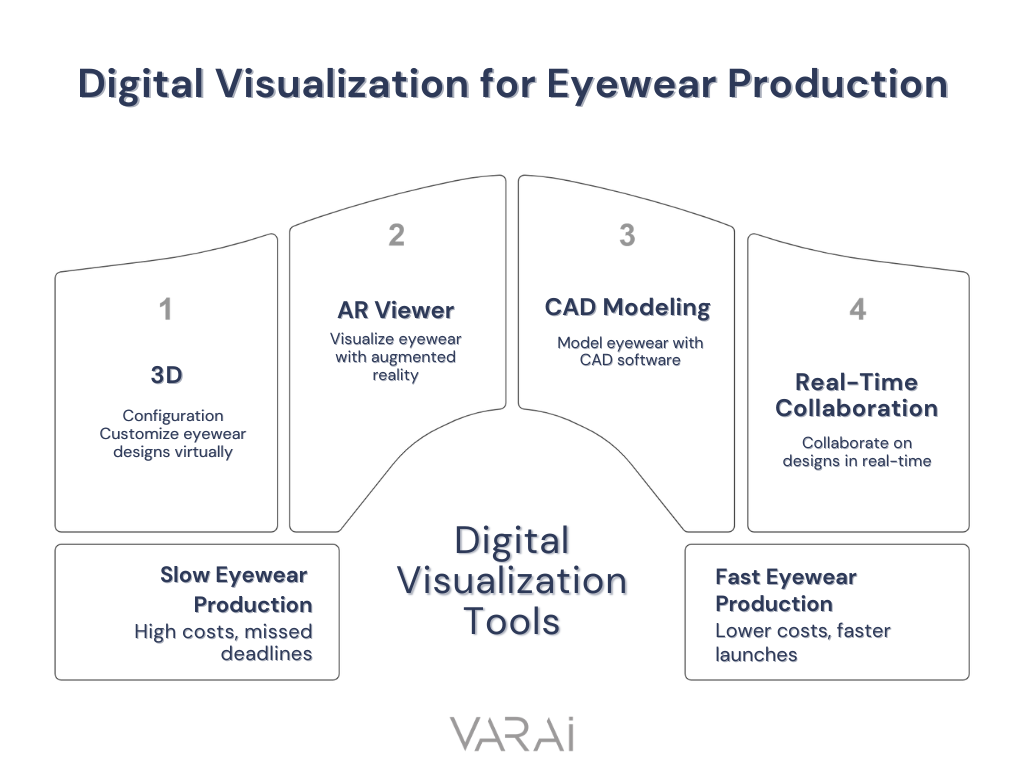

Can Digital Visualization Help in Cost Reduction and Speed?

Without digital visualization, companies have always had problems with:

- Design cycles are slow and highly repetitive.

- Physical prototypes drive material costs up fast.

- Approvals lag due to unclear visual communication.

- Fit and stress issues appear post-production.

- Teams misalign due to inconsistent design data.

- Scalable customization is slow and cost-heavy.

- Missed deadlines delay launches and market entry.

But, thanks to various digital visualization tools and software such as:

- 3D Configurator

- Augmented Reality Viewer

- Virtual Try-On Tool

- CAD Modeling Software

- 3D Rendering Engine

- Material Simulation Tool

- Photorealistic Visualization Software

- Lens Simulation Software

- Real-Time Collaboration Platform

By embedding these tools into technical workflows, eyewear brands gain three major advantages:

- Faster development

- Lower production waste

- Unmatched design fidelity

These benefits can help you easily reduce the costs and speed issues associated with eyewear production. Let’s learn further how digital visualization is helping companies with both.

Digital Visualization for Costs

Traditional eyewear production faces three persistent cost drivers: slow design cycles, wasteful prototyping, and rework from errors. Digital visualization cuts deeply into all three.

- Fewer physical prototypes: Designers can test and adjust frame models virtually, reducing the need for costly, iterative samples.

- Less material waste: Visualization tools identify design flaws before production begins, avoiding scrap from misaligned cuts or incorrect fits.

- Smarter resource allocation: Teams spend less on guesswork and more on validated, precision-driven development.

Digital Visualization for Speed

Speed to market is critical in a trend-sensitive industry. With real-time visualization, design teams can make rapid adjustments, get stakeholder feedback faster, and approve concepts in a fraction of the time.

Visualization also bridges the communication gap between design, engineering, and manufacturing, ensuring all departments work from the same accurate model. Manufacturers using digital visualization consistently outperform on timelines and flexibility.

Conclusion

Digital visualization might be the key that all eyewear manufacturing companies are looking for. It is helping with faster development, greater personalization, and reduced production costs.

From virtual try-ons to 3D printing, it improves every step of the process. By simulating, testing, and refining designs digitally, brands gain precision without delays or excess waste. Choosing such visualization tools for digital platforms can help many eyewear brands plan months in advance.

So, are you looking for the most advanced virtual eyewear visualization software?

VARAi is your all-in-one solution. From automated eyewear prototyping to real-time VTO’s, our platform supports complete customization, ultra-accurate technical design, and fast iterations.

And if you are looking for content creation of eyewear, VARAi’s AI-powered tools can help you outperform in marketing, sales, and design. Whether you’re creating smart glasses, lenses, or 3D-printed frames, you can use VARAi’s 3D eyewear configurator to help you visualize it all, reduce costs, and bring products to market 120 days ahead of your competition.