What does it really take to bring an eyewear design to life?

The answer might surprise you.

Even today, many eyewear brands rely on outdated, analog workflows. Think hand-drawn sketches, 2D technical drawings, slow physical prototypes, and countless rounds of back-and-forth. From the first concept to final production, the process can drag on for six to nine months.

That kind of timeline might have been acceptable in the early 2000s, but in a digital-first world where trends shift overnight, it’s become a liability.

While industries like fashion, architecture, and automotive have adopted AI and 3D visualization to speed up eyewear design process and reduce waste, eyewear has been left behind.

Until now.

What Eyewear Design Process Looks Like Today and Why It’s Broken?

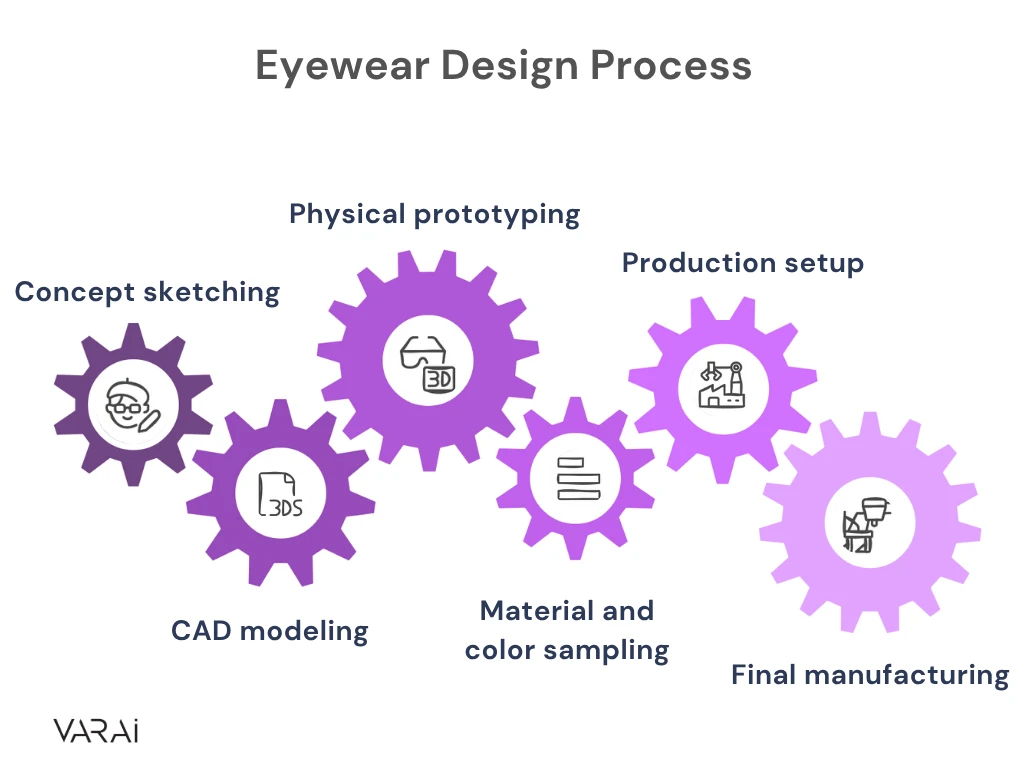

Let’s break down the current design process for eyewear that most brands still follow:

- Concept sketching (often by hand)

- CAD modeling for technical specs

- Physical prototyping and sample reviews

- Material and color sampling

- Production setup and supplier handoffs

- Final manufacturing + logistics

Even for seasoned design teams, this can take half a year or more.

There’s also a layer of invisible complexity: base curve adjustments, pupillary distance alignment, temple flex, nose bridge dynamics, material selection. Every decision has to work in harmony across fit, aesthetics, and function. Now imagine doing that with only 2D tools and your imagination as the best tools for eyewear process designing.

That’s not just inefficient. It’s risky.

Other Industries Left 2D Behind Years Ago

Several industries have already moved past analog workflows, proving that digitization is essential for innovation and efficiency.

Let’s compare:

- Fashion brands now simulate collections digitally before a single stitch is made.

- Automotive manufacturers use digital twins to validate safety before building prototypes.

- Architects design entire cities in immersive 3D environments.

Some statistics about these industries also tell us why their change helped them increase their revenue and serve their customers better.

Fashion:

- Over 50% of Hugo Boss’s collections are now created digitally, dramatically reducing sample iterations and accelerating time-to-market.

- Major brands like Gucci, Dior, and Chanel are digitizing garment layers (including interlinings) to achieve true-to-life 3D visual fidelity.

Automotive:

- 76% of automotive companies use digital twins today, making it the second-highest adopter across industries.

- 97% report that digital twins improve new product development, and 92% say they boost sustainability and reduce waste.

- 38% of these companies expect digital twins will make physical prototypes obsolete within four years.

Architecture, Industrial & Aerospace:

- Around 75% of advanced-manufacturing companies (including aerospace & auto) now deeply integrate digital twin technology as a standard design tool, according to McKinsey.

- The global digital twin market surged from €16.4 B in 2024 to an expected €240 B by 2032, with manufacturing leading the way

So why is eyewear, a multi-billion-dollar global market, still reliant on 2D drawings and physical back-and-forth? Why can’t the eyewear design process become more adaptive?

The answer used to be: there were no tools specialized for this niche.

But not anymore.

Enter VARAi: AI + 3D Tools Built Just for Eyewear

VARAi is an AI-powered eyewear platform built specifically to solve this analog bottleneck. These tools use the current guidelines for eyewear design process, including lenses and frames. Based on traditional analog manufacturing processes, these standards help brands design eyewear that is safe, high-performing, and comfortable for the wearer.

They can still serve as a foundational reference when creating standardized eyewear that meets regulatory expectations for durability, fit, and functionality.

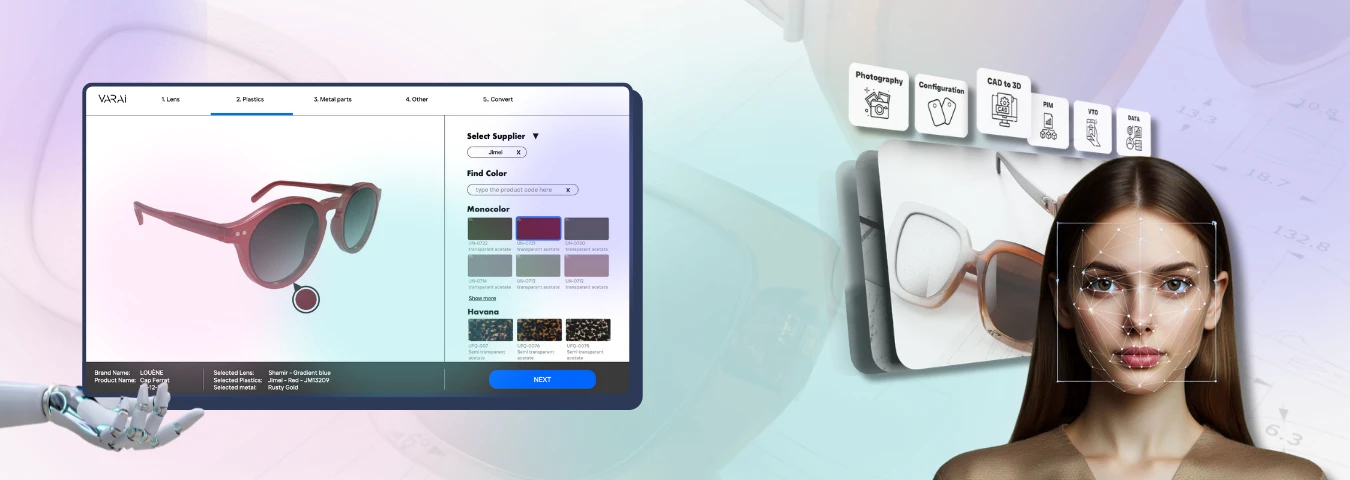

It empowers brands, designers, and manufacturers to create, visualize, and iterate on frame designs in real-time, all through an intuitive 3D configurator.

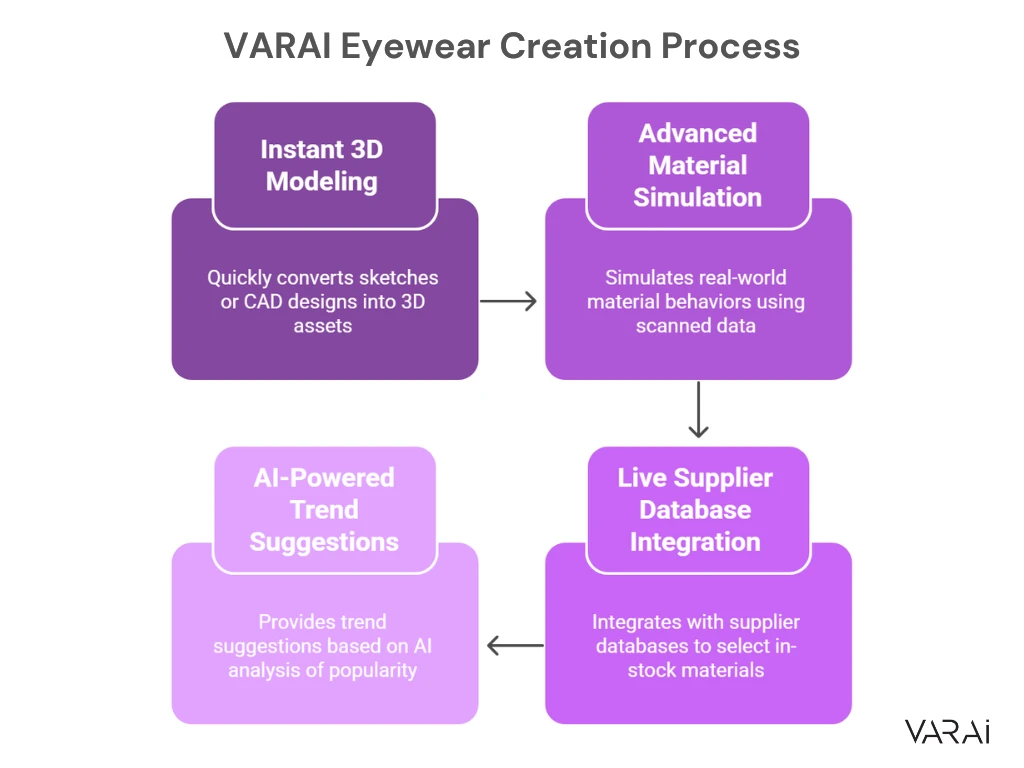

Here’s how it’s transforming the process:

- Instant 3D Modeling: From sketch or CAD to photo-realistic 3D asset in minutes.

- Advanced Material Simulation: Transparent lenses, matte acetates, glossy metals, all behave like their real-world counterparts using scanned data and machine learning.

- Live Supplier Database Integration: Select only in-stock materials, matched by thickness, style, and availability.

- AI-Powered Trend Suggestions: Know what colors, shapes, and finishes are rising in popularity and design accordingly.

It’s a full-stack studio for eyewear creation, optimized for speed, precision, and flexibility.

Beyond Design: Unlocking Next-Level Product Experiences

The benefits don’t stop at faster eyewear design process.

Once your eyewear exists as a high-fidelity 3D model — you unlock a world of new business opportunities:

- Virtual Try-On Integration: Let customers try before they buy, even on mobile.

- 3D Viewer for E-Commerce: Show off every curve, hinge, and color shift from all angles.

- AI-Generated Model Photography: Skip the photoshoots, create beautiful lifestyle visuals without models or royalty fees.

- Instant Packshots: Use your 3D assets for high-res product photos ready for Shopify, Amazon, and catalogs.

This is how brands cut production cycles in half, reduce waste, and launch collections faster — all without compromising on quality or creativity.

Why Speed-to-Market Now Defines Success?

The consumer goods market needs speed as much as it needs creativity. The brands that win are the ones that can design, adapt, and launch, all in record time.

In eyewear, traditional production cycles of 6 to 9 months make it nearly impossible to stay ahead of trends. But with AI and 3D-powered workflows, those timelines can shrink dramatically.

Designers and brands can now:

- Move from sketch to fully rendered 3D model in a matter of hours

- Launch digital marketing campaigns before physical samples even exist

- Iterate designs faster based on real-time market feedback

- React to seasonal trends without overproducing or overcommitting

This speed doesn’t come at the cost of quality, it actually enhances decision-making. With early-stage visuals and accurate material previews, teams can align faster and avoid costly delays.

In a world where relevance has an expiration date, being able to go from concept to consumer in weeks, not months, is the real competitive advantage.

Setting a New Standard for Modern Eyewear Brands

This shift isn’t just about new tech. It’s about building a better eyewear industry, one that’s:

- Faster

- Smarter

- More creative

- More sustainable

- More accessible

From boutique designers and DTC startups to global OEMs and licensed labels, AI and 3D workflows are becoming the new standard, and platforms like VARAi are leading the way.

Because in the end, this isn’t just about design.

It’s about bringing better eyewear to market, faster, cleaner, and with total creative freedom.

Conclusion

Eyewear is finally catching up with the digital age. As AI and 3D tools reshape outdated design workflows, brands now have the speed, precision, and flexibility needed to thrive in a trend-driven market. This shift isn’t just technological, it’s strategic for many brands.

By embracing the digital eyewear design process, eyewear brands can reduce waste, accelerate launches, and create with confidence. The future of eyewear isn’t just faster, it’s smarter, more creative, and fully within reach.

VARAi’s Design Studio is Your Most Needed Package!

Ready to take your eyewear design process to the next level? VARAi’s all-in-one eyewear design studio lets you go from concept to shelf, without delays, guesswork, or endless samples.

With VARAi, you can:

- Upload your eyewear sketches or CAD files directly into the design studio

- Select from a rich pre-filled materials library (including Mazzucchelli and Jimei acetates/lenses)

- Upload your own custom materials and apply them instantly using the 3D configurator

- Explore realistic product visuals using a machine learning-powered 3D viewer

- Let your customers interact with designs using integrated Virtual Try-On (VTO)

- Instantly generate high-definition renders for e-commerce or print catalogs

- Create AI-generated lifestyle photoshoots of your entire collection, no photographers, models, or royalty fees required

VARAi removes the friction so you can focus on what matters: designing eyewear that sells.

Want a demo to check out what all you can do? Contact us!